Restore the Beauty and Integrity of Your Caravan or Motorhome. Your Journey Deserves the Best!

AllBrand Caravan Services

Trustworthy Caravan & Motorhome Servicing Solutions to Keep You on the Road!

Our highly skilled technicians possess years of experience and expertise, ensuring that every aspect of your vehicle is thoroughly inspected and serviced. From engine diagnostics and fluid checks to electrical system evaluations and gas appliance inspections, we leave no stone unturned to guarantee your safety and comfort on the road.

Contact us or visit our shop if you need an expert opinion on Lithium battery upgrades.

The Key Areas We Look At Are

AllBrand Caravan & Motorhome Servicing - What It Involves

The electric brake assembly on your caravan consists of a pair of wires (one for each wheel) that run back to the trailer plug. Unfortunately, the majority of these systems use simple crimps or “spade” connectors to make the connections.

At AllBrand, we prefer to take the more solid method of soldering these joints. While it is a little more time consuming, the time spent is well worth it in the end as it offers far greater longevity for the system.

Under the top cylinder of your jockey arrangement, there is a bearing which transfers your caravan’s weight as you wind it. This bearing is composed of a number of metal balls contained in a plastic cassette.

When stripping the jockey down for servicing and lubrication, it is oftentimes the case that the plastic cassette has cracked or split.

In this case you must either replace the bearing, or, risk one of the stray ball bearings entering the shaft of the jockey and leaving it incapable of being wound.

One of the single most important aspects of the service is the wheel bearings of your van. The bearings suffer enormous stresses on the road, and as such must be kept in tip-top shape to avoid problems down the road (metaphorically and literally).

Whilst servicing these, they’ll undergo a thorough wash and repack service, as well as a thorough inspection for defects such as pitting, deterioration of the coating, rusting, or general visual inconsistencies on the surface.

If any of these are picked up, we recommend that they be replaced to ensure the safety of the rig.

Because of the operating conditions of caravan wheel bearings (sporadic use, lots of idle standing, greater direct weight per axle, amongst others) endure, their lifetime is much less than the wheel bearings in a typical roadcar.

Because of the diverse range of caravan setups available, there is a variable range of wear that occurs on the suspension bushes between each individual rig.

Some wear out bushes very rapidly, while others never experience much wear at all.

Some tandem wheel rigs require very frequent attention to avoid spring breakages. We can to some extent re-engineer this aspect of your caravan to improve wear characteristics, as well as advise you on which suspension option will suit your van if you intend on using it on unmade road surfaces.

Unfortunately, brake linings don’t last quite as long as would be ideal.

Oftentimes they can actually crack prematurely, and whilst this doesn’t make the van unworthy for road use, it can produce what would be described as an aggressive braking characteristic.

Once they have actually cracked, you’ll experience much quicker deterioration, and as such it’s wise to replace them as soon as possible once this occurs.

Of your van’s entire braking system, nothing works quite as hard as the brake magnets. Despite that fact, they generally will be good for around 30,000 to 40,000km of road use.

These have wear depth indicators built into their faces, and once these are visible it indicates that a replacement is due. If this is the case, the magnets are replaced and the brake drums are machined to suit.

By design and necessity, caravan marker lights are typically only very basic in quality and construction. Because of their all-weather condition, they oftentimes will experience intermittent function due to water entry or seep.

This means often we have to remove the marker light lenses and give the interior a general clean-up, as well as ensuring the ground screw is secure and tidy.

Although the windup system commonly found in Jayco caravans is generally reliable, it does require maintenance after around 5 years of lifetime.

It is unfortunately not uncommon for vans which have been either maintained poorly or not at all to break windup cables (which renders the entire roof to wind up), or break a riser arm cable (which renders one riser arm incapable of winding).

This can often be unexpected to find either of these conditions and is sure to cause a premature end to your holiday. Windup servicing inspects and lubricates the entire windup system to ensure it is in peak condition.

In order to access these windup mechanisms, we empty the cupboards as all internal panels which impede access to the windup system will need to be removed.

Amongst other things, we pay close attention to the following:

- Condition of the main winch cable

- Condition of the main winch clutch

- Condition of the 4 riser arm cables

- Operation and lubrication of the several pulley wheels which transfer motion from the main winch to the riser cables

- Connection of the pushrods and lubrication

- Lubrication and condition of the 4 riser arms

- Ensuring floor plates are still well anchored on pushrod assemblies

Check Out the AllBrand Blog

Get the latest caravan news, tips, and tricks right here.

10 Reasons Why Camping or Caravanning is Good for You

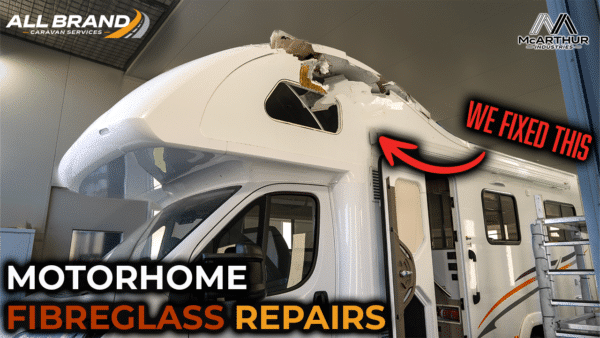

Professional Motorhome Fibreglass Repairs in Brisbane

Get the Best Parts and Service for Your Caravan or Motorhome Today

Book a 15-minute call with our head technician now for free (normally $65) to get started.